|

|

| HRP 4Y.KO series comparators comprise two components, professional weighing platform (a new mechanical design of electromagnetic mechanism housed within a tight steel casing) and PUE 7.1 terminal more ... |

| Laboratory Equipment > Analytical Balances > Mass Comparators | ||||||

|

||||||

OverviewHRP 4Y.KO series comparators comprise two components, professional weighing platform (a new mechanical design of electromagnetic mechanism housed within a tight steel casing) and PUE 7.1 terminal

Capacity x Readability

Manufature:

RADWAG1050 kg x 10 g Pan Size 1000 x 800 mm SKU: HRP 1000.4Y.KB |

||||||

HRP 4Y.KO series comparators comprise two components, professional weighing platform (a new mechanical design of electromagnetic mechanism housed within a tight steel casing) and PUE 7.1 terminal.

The weighing platform made of steel features centring rings enabling precise positioning of the weights. Precisely marked weighing platform PUE 7.1 indicator with 5.7" color graphic display ELECTRONIC LEVEL INDICATOR

Functions

DATA EXCHANGE THROUGH USB STORAGE DEVICES

INFRARED PROXIMITY SENSORS

INTERFACES

| Model | HRP 1000.4Y.KB | |

|---|---|---|

| Capacity x Readability | 1050 kg x 10 g | |

| Repeatability nominal load * | < 10 g | |

| Repeatability for small load* | < 6 g (200 kg) | |

| Stabilization time | 10 s | |

| Adjustment | External Calibration | |

| Electric compensation range | 0 g ÷ 1050 kg | |

| Eccentricity (for test weight) | 1 d / 5 mm | |

| Maximum permissible weight loading speed | 0.6 m / min | |

| Recommended weight loading speed | 0.3 m / min | |

| OIML calibration range E1 | - | |

| OIML calibration range E2 | - | |

| OIML calibration range F1 | - | |

| OIML calibration range F2 | - | |

| OIML calibration range M1 | 1000 kg | |

| OIML calibration range M2 | 200 kg ÷ 1000 kg | |

| Display | 5.7" color resistive touch screen | |

| Keypad | 8 keys | |

| Ingress protection - indicator | IP 43 | |

| Touch-free operation | 2 programmable sensors | |

| USB-A | 2 | |

| Ethernet | 10 / 100 Mbit | |

| RS-232 | 2 | |

| Wi-Fi | 802.11 b/g/n | |

| IN/OUT | 4 x IN, 4 x OUT | |

| Power supply | 110 ÷ 230 V AC / 50 ÷ 60 Hz | |

| Operating temperature | +15 ÷ +30 °C | |

| Operating temperature change rate | ±2 °C / 12 h | |

| Relative humidity variations | ±10% / 4 h | |

| Relative humidity*** | 40 ÷ 60% | |

| Transport and storage temperature | –20 ÷ +50 °C | |

| Weighing pan dimensions | 1000 x 800 mm | |

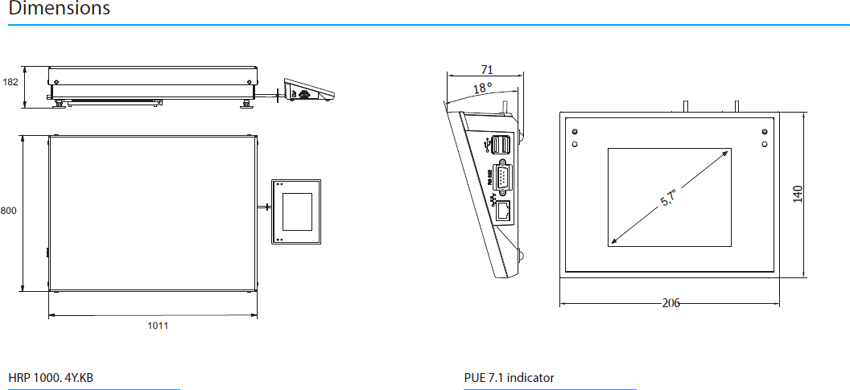

| Mass comparator dimensions | 1011 x 800 x182 mm | |

| Indicator dimensions | 206 x 140 x 71 mm | |

| Mass comparator net weight | 134 kg | |

| Mass comparator gross weight | 168 kg | |

| Mass comparator packaging dimensions | 1200 x 1000 x 436 mm | |

| Ambient Conditions THB-S or THB-P sensor |

Peripheral Devices Epson dot matrix printer barcode scanner |

| Cables, Converters RS-232 – P0108 computer cable RS-232 – P0167 computer cable RS-232 – P0151 Epson printer cable |

Electrical Accessories power supply with ZR–02 battery |

|

||||